By David Dodge and Kay Rollans

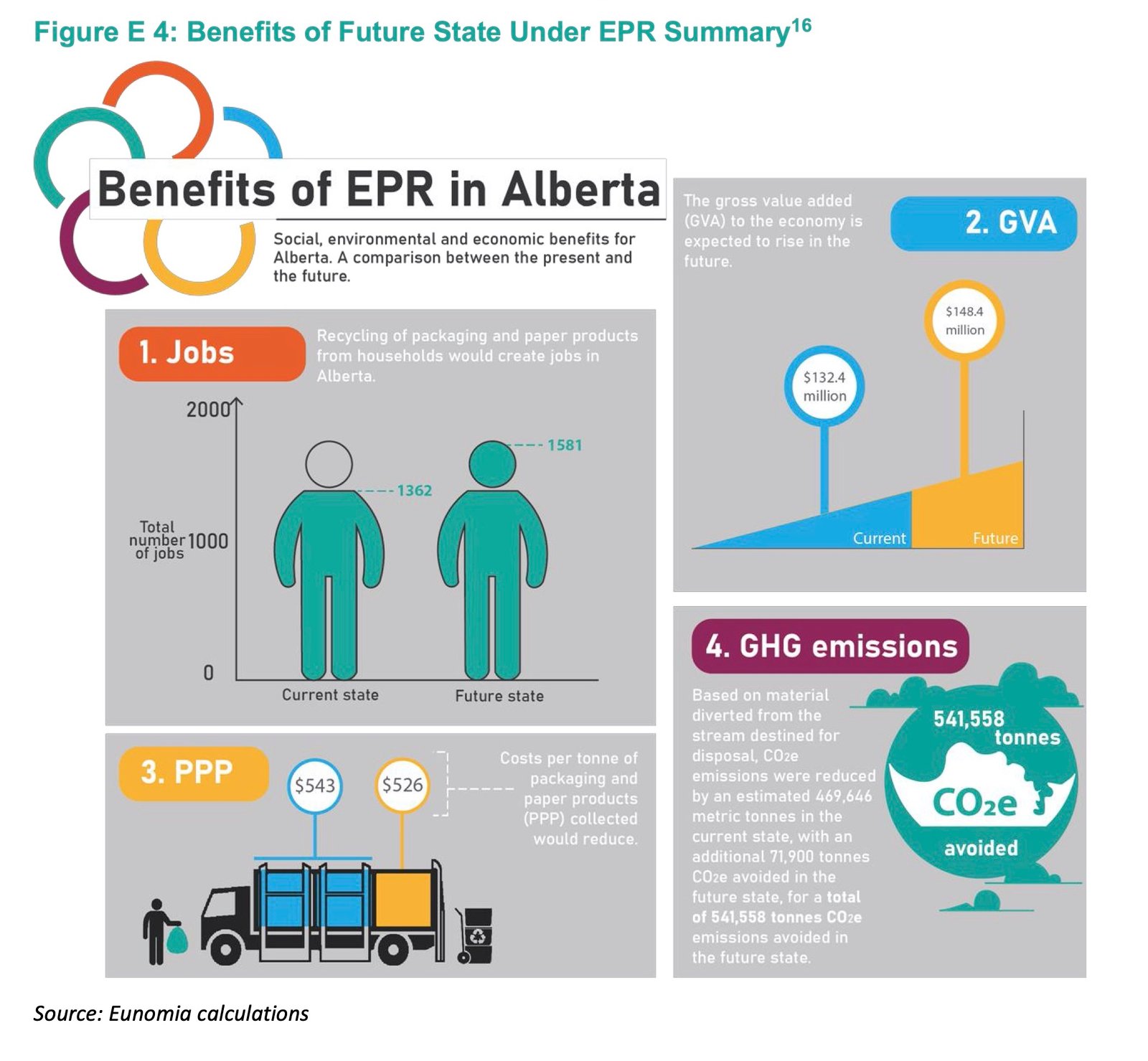

According to a new study, implementing extended producer responsibility, or EPR, in Alberta would not only save taxpayers money, but would lead to more waste being recycled, create new jobs, and benefit the environment.

Shifting responsibility back on to the producers would save municipalities in Alberta $105 million per year in paper and packaging products (PPP) recycling says the study funded by the cities of Calgary and Edmonton, the Alberta Recycling Council and others.

EPR and the circular economy

EPR is a key piece in the circular economy pie. A circular economy aims to circulate and recirculate already existing materials and products through reuse, recycling, refurbishing, and repurposing in order maximize their use and value. This, ultimately, helps accomplish another big R: reducing waste by reducing the amount of new material that enters the economy.

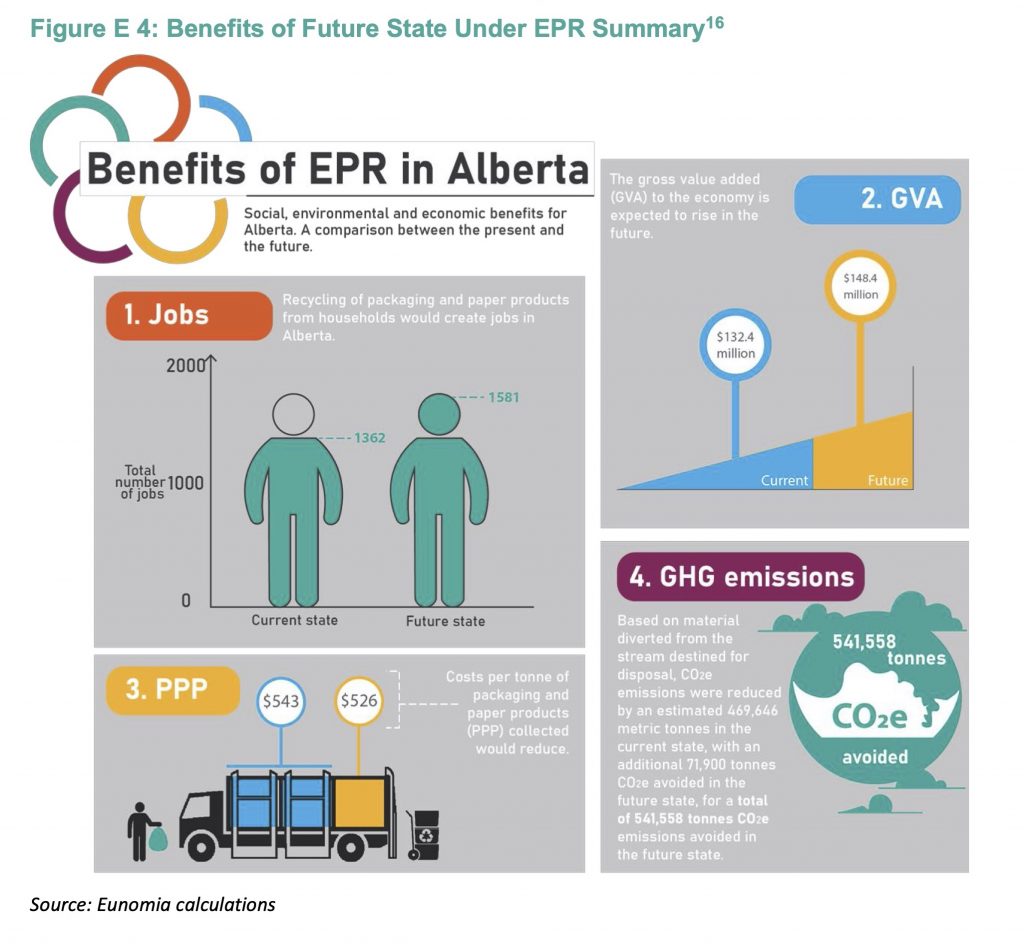

In non-EPR recycling programs such as the blue box, producers create paper and packaging products, but municipalities and individual citizens are ultimately responsible for figuring out how to manage this waste. In EPR programs, things look different: “The role for the producer who made that product and package does not end when they sell it,” explains Christina Seidel, the Executive Director of the Recycling Council of Alberta. EPR lays the financial and operational responsibility for managing and processing post-consumer waste on the producer.

Albertans will already be familiar with the EPR for beverage containers: we call it the Bottle Depot. Customers are encouraged to return their beverage containers to producers through a deposit system. The producers then handle the recycling of these containers themselves. It’s a system that works, diverting 86 per cent of beverage containers sold in the province from landfills every year.

“Assigning such responsibility can … provide incentives to prevent waste at the source, promote product design for the environment and support the achievement of public recycling and materials management goals,” the study explains.

EPR an all-around good idea

EPR for PPP and other products has already been implemented in many jurisdictions around the world, including five provinces in Canada. That, says Peter Demong, Calgary City Councillor and Vice President of the Alberta Urban Municipalities Association, is because it works. “EPR for PPP is already at work for and benefiting more than 80 per cent of Canadians… It empowers companies to do what they do best, and it saves municipalities and their ratepayers millions of dollars in recycling collection fees every year.”

The study projects significant benefits for Alberta. “It’s estimated that the economy in the province will have an additional 16 million dollars in investment in it,” said Seidel, adding that “approximately 220 new jobs would be created in the recycling industry.”

Meanwhile, she says municipalities would save in $105 million per year. “That’s the kind of money that the producers would be putting into the system rather than the municipalities having to pay for those recycling systems.”

But doesn’t this come at a heavy cost to producers?

Seidel says that producers are currently some of the biggest supporters of EPR. This, the study explains, is because EPR offers producers more control over their products, from the design stage to repurposing and recycling all the way through to end-of-life.

“Producers are willing to take on new responsibilities and costs because this full control is part of a long-term strategy that allows them to innovate, compete, and reduce costs. They want producer responsibility applied broadly and fairly, to create a level playing-field where innovators are rewarded for their efficiencies and free-riders are penalized for not following the rules,” the study explains.

One of the coolest factors is EPR creates a powerful disincentive for producers to produce packaging and waste that is hard to recycle. In the present system hard to recycle materials land in municipal waste management system and the public pays for the problem. And as we’ve seen in the past, this is how some materials wind up in shipping containers, dumped in foreign countries.

We’ve become very complacent about recycling and EPR is seen as the way to rethink recycling in a way that begins to support the circular economy. Let’s look again at beverage container recycling: an EPR model that has turned into a $350 million industry in Alberta, employing over 3,100 people.

“We haven’t talked to hardly anybody who thinks … this is a bad idea. It is such a good idea,” said Seidel. “the fact that those who are going to end up paying the bill at the end of the day are some of the strongest advocates really speaks to how good this is.”

EPR reduces emissions

Making producers responsible for their own waste encourages producers to look at their waste as a resource in itself—something that avoids the cost of disposal and creates value through reuse. It also creates incentives for those producers to make products and packaging that are as efficient to manage as possible.

This approach will provide enormous environmental benefits for Alberta.

“We’re going to recycle 21,000 more tons of packaging and paper products every year,” said Seidel. This, she says, will reduce carbon dioxide emissions in the province by 72,000 tons. “That is the equivalent of pulling 15,000 cars off the road for a year,” she said.

And that’s just with EPR that extends to paper and packaging products. As EPR programs expand to handle a wider range of products, the energy and emissions savings will only increase—as will the economic returns.

Seidel suggests Alberta take a page from British Columbia’s EPR book. The province has EPR frameworks governing the management of everything from batteries to used oil, and from unused medication to, most recently, electronic and electrical equipment.

“Continued and increased advocacy is really critical,” says Seidel. In these trying economic and environmental times in Alberta, we need to start implementing solutions—and fast. “We just need to tell our leaders that this is not just a good idea, but it’s a necessary idea.”

The Eunomia report “Extended Producer Responsibility for Residential Packaging and Paper Products” is a third-party report executed on behalf of the Alberta Urban Municipalities Association, the Cities of Edmonton and Calgary, and the Canadian Stewardship Services Alliance. It was published December 6, 2019.