Aerial view of the Greenfield Global industrial alcohol plant and Truly Green Farm’s 45 acre greenhouse in the background. Photo Greenfield Global

By David Dodge and Scott Rollans

A greenhouse operator is standing outside a farm show in Woodstock, Ontario. He turns to a man who runs an ethanol plant and says “Wouldn’t it be cool if we could use your waste heat to heat my greenhouse?”

This burst of unexpected synergy sounds like an imaginary scenario dreamed up by a trade-show promoter. The difference is, this actually happened, back in 2010 at the Woodstock farm show. The greenhouse guy was Hilco Tamingo of Truly Green Farms, and the ethanol plant guy was John Creighton of Greenfield Global, based in Chatham, Ontario.

In 2014 we did a story on Truly Green Farms and Greenfield Global partnership. By then Truly Green Farms had already built a 22.5-acre greenhouse right across the street from Greenfield Global’s ethanol plant. The project had the potential to become one of Canada’s most remarkable examples of industrial symbiosis—one company making productive use of the waste from another.

This past December, seven years after the farm-show brainstorm, Truly Green Farms and Greenfield threw the switch on their innovative heating system. The Truly Green greenhouse now draws its heat from the Greenfield refinery stack across the street.

“We have two insulated lines that also go underneath Bloomfield Road from the Greenfield Global plant over to the Truly Green Farms into our boiler room,” explains Greg Devries, a partner at Truly Green Farms.

A heat exchanger harvests the 65-to-70 degrees Celsius heat from Greenfield, and sends hot water out to heat the greenhouse.

Truly Green still has three traditional gas boilers, but they’re currently shut down, even though it’s the dead of winter. “They’re not putting out any CO2, which is a win for the globe,” says Angelo Ligori, senior advisor with Greenfield.

In other words, heat that was formerly wasted often covers all of the heating needs of a 45-acre greenhouse operation, even in the coldest months of the year.

After so much work and effort over the past seven years, the moment of triumph actually felt slightly anticlimactic. “There was little apprehension flicking the switch,” Devries says. “You kind of have to squint and look away when you hit the switch, because you are afraid something might theoretically blow up. But, it actually went relatively smooth.”

The tip of the iceberg

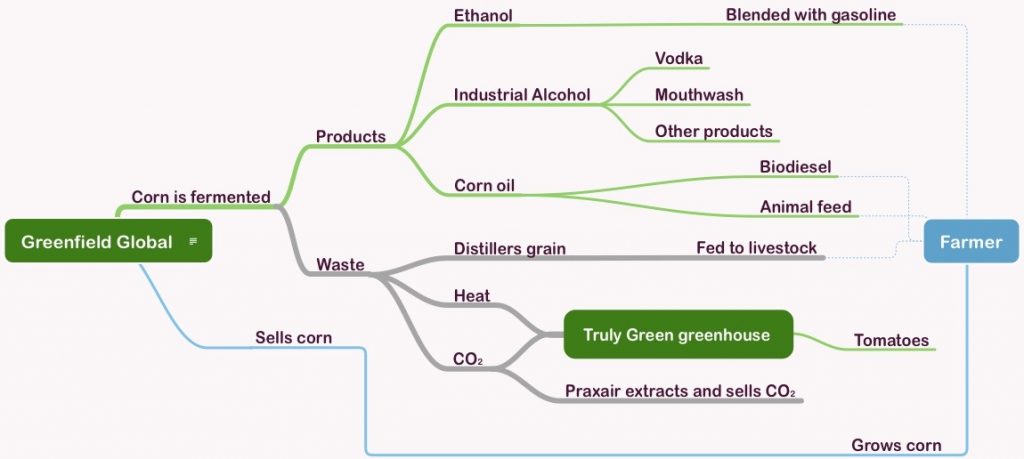

As cool as it is the Truly Green greenhouse waste heat project is just one small part of the Greenfield story. The ethanol plant also has a number of other initiatives in place, making it one of the best examples we’ve found illustrating a virtuous cycle of industrial symbiosis.

Greenfield’s Industrial symbiosis in action:

Products from corn

• Farmers sell 500,000 tonnes of corn to the Greenfield ethanol plant each year.

Greenfield produces 60 million liters of ethanol per year. This is sold and blended into gasoline.

• Greenfield also produces 140 million litres of industrial alcohol per year. This is used to make vodka, mouthwash and a host of other products.

• Greenfield produces 3,500 tonnes of corn oil, which is sold and used to make biodiesel fuel and animal feed for chickens and turkeys.

Transformed waste

• Greenfield produces 150,000 tonnes of distillers’ grains; farmers buy this and feed it to livestock.

• Greenfield’s waste heat (enough to heat 1,000 homes) is used to heat Truly Green Farm’s greenhouse.

• Greenfield has reduced its CO2 emissions by 120,000 tonnes per year, thanks to Praxair capturing and selling CO2 and Truly Green Farms capturing and using CO2 to grow tomatoes.

In this virtuous cycle, Greenfield is successfully closing the loop between raw materials, products and waste. Truly Green Farms puts Greenfield’s waste (heat and CO2) to use growing tomatoes. At the same time, Greg Devries and other farmers like him sell corn to Greenfield as a raw material. They also buy many other products from the biorefinery, including distillers grains (to feed cows) and fuel (ethanol in gasoline, and biodiesel).

This pioneering industrial symbiosis partnership required an enormous amount of commitment, trust, creativity, and investment. As Devries explains, “It was an $8 million capital investment that both companies agreed to participate in.”

That investment will pay for itself over time. Even after Truly Green Farms finishes a planned expansion, which will double its greenhouse space to 90 acres, the company expects to save fully half of its heating costs.

In this amazing example of industrial symbiosis, a pipe runs under the road carrying heat and carbon dioxide from the Greenfield Global ethanol plant stack to the Truly Green Farms greenhouse. Photo David Dodge, GreenEnergyFutures.ca

The new carbon economy

The Greenfield-Truly Green partnership has put the two companies at the forefront of the new carbon economy. “Now, we’re working through exactly who gets the [carbon] credits and how all that works out,” says Ligori. “But it’s a great, great story for our global warming initiative that the world is on. And, company-wise, this is a significant contribution that we’ve made to Ontario.”

Devries not only sees energy savings and carbon reductions in this initiative, he hopes someday their food products will command a higher value from consumers as well.

Encouraged by this project, Truly Green Farms is now looking to close the loop on its own wastes. “We have a stream of waste—prunings at clean-out time, and tomatoes that don’t make grade—and a lot of that organic matter ends up going to the landfill,” says Devries. “Is there a way that we can produce our own gas, that would allow us to produce our own electricity, so we can offset that expensive kilowatt of electricity?”

Video from our original story about Greenfield and Truly Green. Although Devries describes himself as low key, he says they’re planning to take some time to pause and celebrate their accomplishment, in the hope of inspiring other entrepreneurs. “I would be the first to encourage them to pursue those dreams,” says Devries. If we can do this, I’m sure there are other people out there who can do even greater things.”